As consumers and designers are becoming more aware of the materials used in their products, new innovations are being developed to meet the need for sustainable textiles. From organic materials to less chemicals used in the production process, manufacturers are testing the limits on what can function and succeed in the consumer and commercial textile markets.

Here are three recent innovations in textile technology that are addressing the issue of sustainability and alternative materials:

Piñatex™ from Ananas Anam

Image Credit: Ananas Anam

Ananas Anam has developed an innovative, natural and sustainable non-woven textile called Piñatex™ made from pineapple leaves fibers. Piñatex has evolved from seven years of research and development to create a natural textile from waste plant fibers.

Piñatex harnesses advanced technologies to create a totally sustainable high performance natural textile. Original development leading to Piñatex™ took place in the Philippines, but finishing, research and continuing development are now being undertaken in the UK and Spain.

Piñatex provides new additional income for farmers while creating a vibrant new industry for pineapple growing countries. Piñatex fibres are the by-product of the pineapple harvest. No extra land, water, fertilizers or pesticides are required to produce them.

Piñatex involves a patented pending technology that protects both the process and the finished material.

The fibers that make Piñatex™ come from pineapple leaves. The fibers are extracted from the leaves during a process called decortication, which is done at the plantation by the farming community. Furthermore, the by-product of decortication is bio-mass, which can be further converted into organic fertilizer or bio-gas. The fibers then undergo an industrial process to become a non-woven textile. The final step in the making of Piñatex™ takes place at a textile finishing company in Spain.

Orange Fiber from Salvatore Ferragamo

Image Credit: Salvatore Ferragamo

The first fabric in the world to be made with citrus fruits, Orange Fiber, was developed for a Salvatore Ferragamo Capsule Collection enhanced by exclusive Designer Prints from the award winning Mario Trimarchi, Compasso d'Oro 2016.

For this project, the company used solely sustainable fabrics of natural origin and is the first brand to use the Orange Fiber — a twill that looks and feels like silk.

The textile is made from citrus waste and can be used for different blends. The first prototypes, a lacelike fabric blended with silk and another blend more similar to satin, were presented in 2014, during Vogue’s Fashion’s Night Out. The first part of the process takes place in Sicily, where citrus cellulose is extracted, then the raw material is sent to a Spanish spinner partner and finally it comes back to Como, Italy, where another partner transforms it into an exclusive textile.

The prototypes produced are similar to silk, with a soft, drapy, light feel. They can be colored and printed as traditional textiles — ink-jet printing and natural colors included.

Compared to existing man-made fibers from cellulose, either from wood or from hemp and bamboo, the orange fiber does not require dedicated yields alternative to food consumption, but reuses a waste product, thus saving land, water, fertilizers and environmental pollution.

OrganoTex® from OrganoClick

Image Credit: OrganoClick

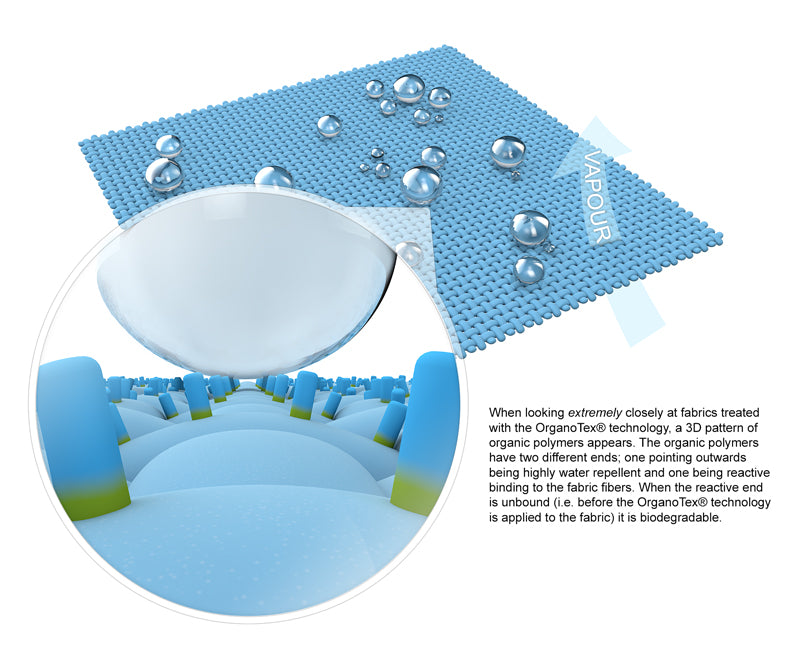

OrganoTex® is a fluorocarbon-free water repellent technology developed with inspiration of the Lotus-flowers 3D-structure. The technology provides functional fabrics with durable protection against water, snow and water-based soiling such as stains from red wine, coffee, ketchup, etc. The water repellency is highly durable and withstands numerous cycles of home laundry.

The OrganoTex® technology is free from fluorocarbons (e.g. PFOS, PFOA, etc) and other accumulative chemicals that negatively affect ecosystems. It is also free from hazardous chemicals, such as isocyanates that may cause respiratory problems. In addition OrganoTex® is readily biodegradable in accordance with OECD 301 C.